Industry

WAGNER is a leading global supplier of industrial surface finishing systems with extensive experience in a wide range of sectors. Whether complete systems or single components – we offer the ideal solution for your individual application.

Put quality

on repeat.

Visit us at PaintExpo!

April 9 - 12, 2024

Simply magical powder coating.

With our new Sprint 2 manual unit.

Reference projects

Our products in use

WAGNER is a leading global supplier of industrial surface finishing systems with extensive experience in a wide range of sectors. Whether complete systems or single components – we offer the ideal solution for your individual application.

WAGNER provides components and solutions for the manual and automatic application of liquid, solvent and water-based coatings. Our focus is on reliability, durability and high, process-safe coating quality of surfaces.

We supply a wide range of custom-built solutions for powder coating applications. These solutions stand out through their versatility, quick color changes, ability to be cleaned easily and environmentally friendly powder recovery systems.

Read moreOur bonding and sealing solutions not only enable combinations of new materials and improved quality, but also offer the opportunity to down-size and reduce the weight of products in a simplified production process.

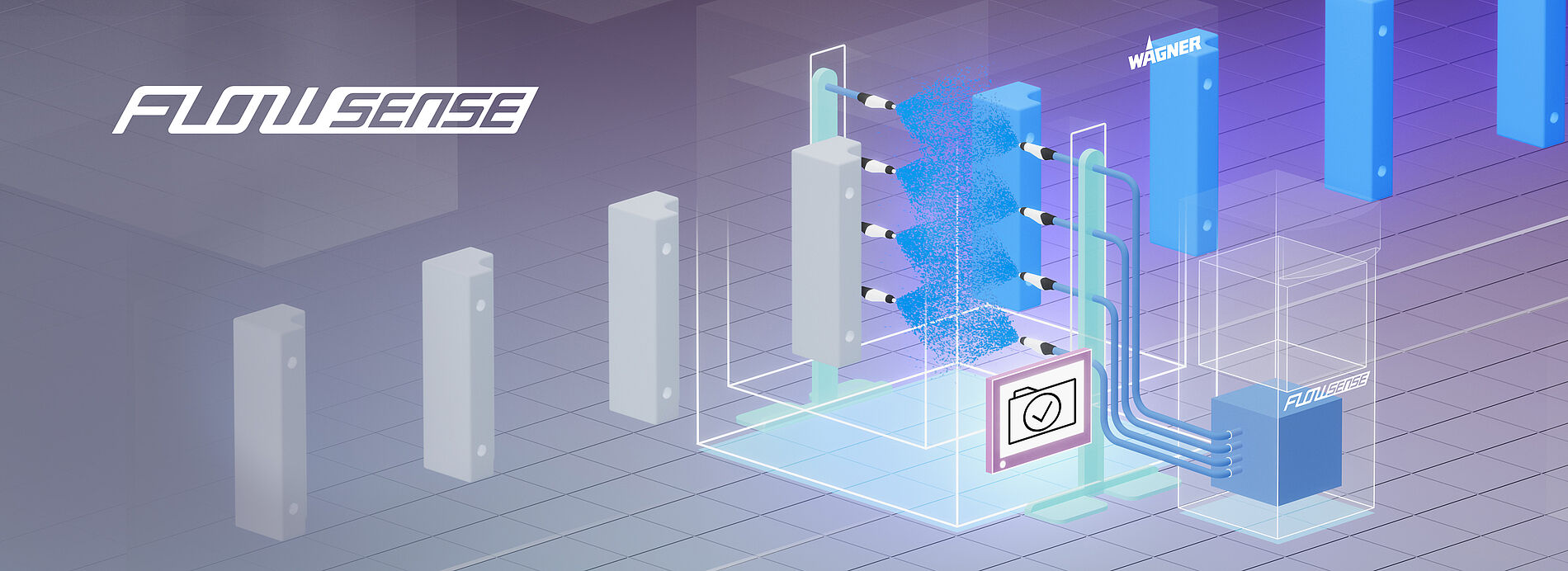

Web-based Internet-of-Things-Plattform for the intelligent visualization of coating systems.

High-speed rotation atomizer with external charge for the efficient application of water-based coatings.

Powder preparation, feeding, dosing and color change are accommodated in a fully automated system.

Highly automated coating of complex automotive wheels with a compact coating unit in a small space.

Automatic moving system for high automatic area coverage with low powder consumption.

Whether in the automotive, wood and MDF, protective coating, household appliance or agriculture, construction and transportation sectors - we offer you the entire technology range and individual solutions for your application.

Our products can be used for various automotive parts, such as plastic, metal interior and exterior components, alloys, steel wheels or decorative parts.

Read moreThe processing of wood workpieces poses special requirements. WAGNER helps you find the right solution for every application.

Read moreOur technologies meet the highest coating requirements for bridges, containers, pipelines or wind and solar power plants.

Read moreHousehold appliances must offer a high level of quality and safety. With our perfectly matched solutions, we achieve reliable surface results for your workpieces.

Read moreTrucks, buses, forklifts, tractors, combine harvesters and motor homes need robust surfaces. We offer you the right technology for each of these products.

Read moreWe present our products at important events worldwide. Come by and get in touch with us.

Read moreBrowse through our latest press articles and read news about our innovative products, subsidiaries, fairs and other activities.

Read moreCurrent product photos and print documents such as catalogs, product and service brochures are available for download in the Mediaplace.

Register nowOur current catalogs provide an overview of all products for a wide range of applications in liquid and powder coating.

Request catalogs